What is Gasification?

Background

As a technology, gasifier or gasification is more than a hundred years old. In terms of small-scale units, it peaked before and after WWII. This was due to the shortages experienced with liquid petroleum, but once oil became available, the gasification units disappeared. You can see some of these early designs on the Old Vehicles page.

Fuel gas, produced by reducing coal and peat, saw use for heating as early as 1840 in Europe. By 1884 it fueled engines in England. Before 1940, gas generator units were a familiar but not extensively utilised technology. However, during World War II, petroleum shortages led to widespread gas generator applications in the transportation industries of Western Europe. (Charcoal-burning taxis, a related application, were still standard in Korea as late as 1970.)

In occupied Denmark during WWII, 95% of all mobile farm machinery, tractors, trucks, stationary engines, and fishing and ferry boats were powered by wood gas generator units. Similarly, in neutral Sweden, 40% of all motor traffic operated on gas derived from wood or charcoal. Likewise, in Europe, Asia, and Australia, millions of gas generators were in operation between 1940 and 1946. See the Gasifier History page for more detailed information.

Torrefaction, Pyrolysis and Gasification

These terms appear interchangeable. However, there are differences in how biomass is thermochemically converted under each process and the end product.

Pyrolysis of biomass takes place at temperatures in the range of 400°C to 450°C which is below the temperature of combustion (850°C – 1,000°C). It converts solid biomass to liquid fuel.

Torrefaction is similar to pyrolysis but takes place at temperatures in the range of 200°C to 320°C. The objective is to create an energy-dense, solid biofuel, which is often called ‘biochar’ or ‘bio-coal’. Click on the link to view our Torrefaction download page.

Gasification takes place at much higher temperatures than pyrolysis and torrefaction. Gas cleaning aims to create a gas suitable for use in an internal combustion engine or electricity generation. There are some ‘gasifiers’ which don’t produce gas for end users. These are simply heating gasifiers used to cook with or heat homes.

Federal Emergency Management Agency (FEM) Gasifier Plans

The use of gasifier technology has ebbed and flowed. However, the steady rise of oil prices sees more significant technological research efforts. Significantly, older designs like those published by FEMA (on our download page here) leave a lot to be desired. Although many new small-scale units are available, there doesn’t yet appear to be much feedback regarding efficiency and where they sit on the development continuum. At the present time, gasifiers on a medium to large scale to generate electricity have more comprehensive applications worldwide.

We have an abundance of biomass to harvest sustainably, but currently, only a fraction generates energy. Available technology for gasification could use a much wider variety and greater quantities of biomass. At the same time provides significant energy while alleviating several pressing environmental concerns. We must take caution when considering using biomass to replace fossil fuels as an energy-dense feedstock due to important sustainability issues

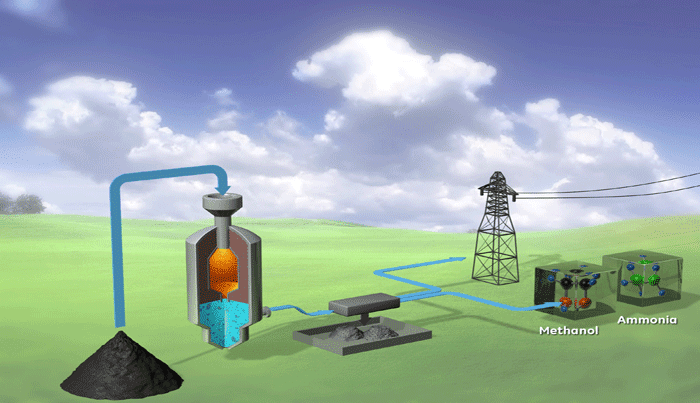

Principles of Gasification

All internal combustion engines run on vapour, not liquid. Before the liquid fuel is injected into the combustion chamber, it is first vaporised. This process is essential for the engine’s optimal performance. Generally, the purpose of a gasifier is to transform solid fuels into gas and to keep the gas free of harmful constituents. Many solid biomass fuels are suitable for gasification, from wood and paper to peat, lignite, coal, rice husks, sawdust, etc. The aim of gasification is the almost complete transformation of this material into a gaseous form so that only the ashes and inert materials remain.

The gasification process begins with pyrolysis, which sees organic material heated up and broken down into gas and liquid components. Heating a wide range of organic matter triggers the gasification process. This releases combustible gases such as carbon monoxide (CO), methane (CH4) and hydrogen (H2). This reaction also produces char water and condensable elements. The residue from this process is char, which possesses a high carbon content and is mainly non-volatile.

The producer gas leaves the reactor with pollutants and, therefore, requires cleaning to satisfy engine requirements. Mixed with air, the cleaned producer gas powers gas turbines (in large-scale plants), gas engines, and gasoline or diesel engines. (Salam, Kumar and Siriwardhana, 2005).

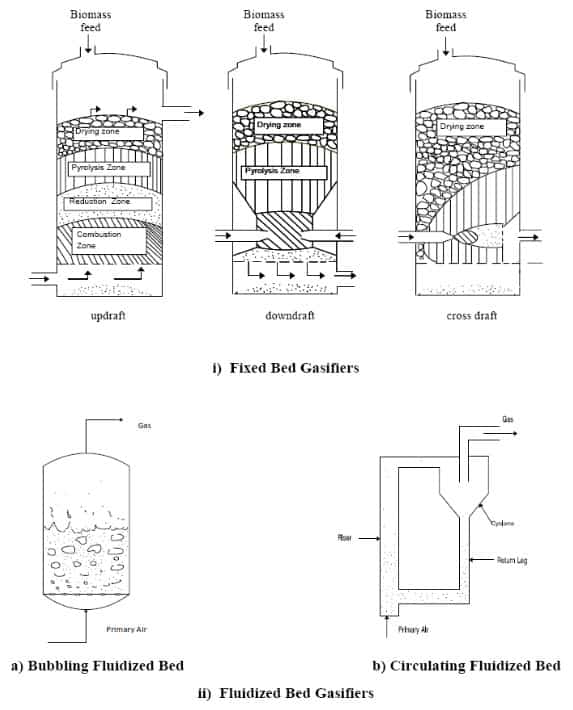

Types of Gasifiers

There are about five significant gasification classification systems. Chiefly, fixed-bed updraft, fixed-bed downdraft, fixed-bed cross draft, bubbling fluidised bed, and circulating fluidised bed gasifiers. Please take a look at the figure below.

What separates these types different is how and where the biomass sits in the reactor vessel—the direction of both air flow and the feedstock. Generally, fixed bed gasifiers are much more straightforward, less expensive, and produce lower heat content, such as producer gas. Conversely, fluidised bed gasifiers are more complicated, more expensive, and have a gas with a higher heating value.

(Source: Salam, Kumar and Siriwardhana, 2005)

Gasifier Tar

It is essential to remove tar when using gasification to power motors or gas turbines otherwise, it could cause substantial operational issues. In contrast, it does not have to be removed when the gas is burned directly in a boiler. “The low tar levels of downdraft gasifiers make them more suitable for uses requiring clean gas”. (Milne and Evans, 1998. See the Academic down load section, the Homepage and Gasifier Reports page.