Junkyard Gasifier

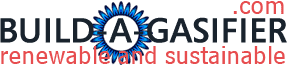

I’ve attached some pictures of my junkyard gasifier built entirely from junk salvaged from the tip. It took about two years to collect enough to do it.

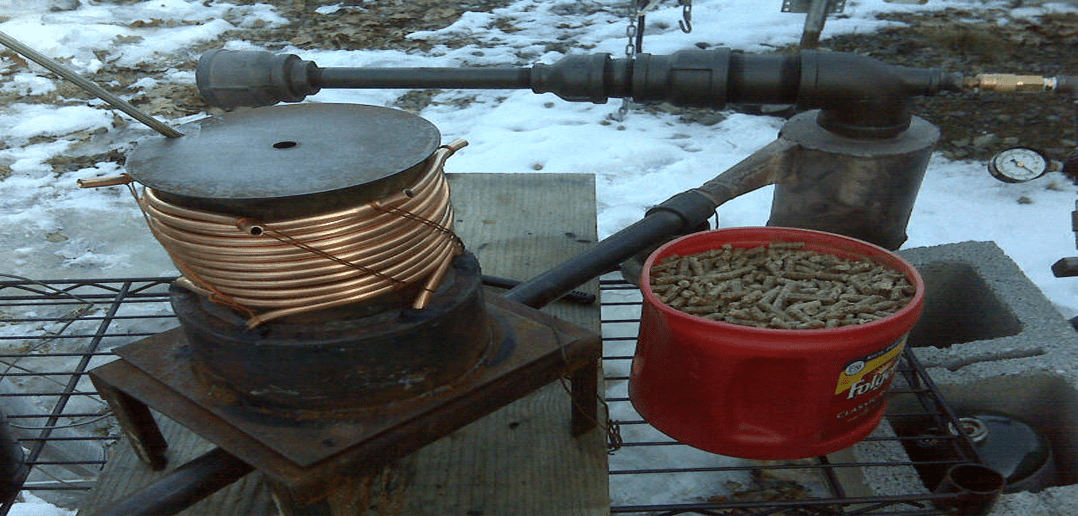

The Pyroliser unit is constructed from an old electric hot water urn boiler; the hopper is a garbage bin turned upside down (FEMA design). The primary gas cooler is made from some thin-walled tube from an old bedhead and is a pretty blue powder-coated colour; the secondary cooler is the same stuff but a nice contrasting red. The water trap is an old jam jar; the Primary filter is made from an old vacuum cleaner with the insides constructed to the FEMA design. The secondary filter is constructed from an old paint tin that happened to fit a used caterpillar bulldozer paper element filter. Most of the odd pipe fittings were from my box of “stuff,” and the various pipes were offcuts from jobs around the farm. The fan is a heater from a Toyota Corolla car dumped at the tip.

The junkyard gasifier is all mounted on an old 6 X 6 pallet. As a result, it is reasonably moveable with the aid of the tractor.

In the pyrolysis itself, I have allowed a secondary air intake (capped off at present). Just in case the primary air didn’t let the temp get hot enough to crack tars. I also have a small inspection port. (It was initially going to be the lighting port, but I decided I didn’t want to pull the whole thing apart to clean it out, so I cut a hole in the side to allow internal access and made it airtight with a silastic gasket).

Junkyard Gasifier First Tests

The first test was spectacular. After about 10 mins, I refuelled the unit and had a backfire, producing combustible gas. I connected it to a 3.5 Kva Honda alternator set and started the generator on petrol. I turned off the petrol, shut off the drawing fan, and closed the valve. The engine faulted and started coughing, then stopped. The mixing valve was too coarse to allow adjustment. So I closed it off, restarted the generator on petrol, turned off the petrol, and controlled the air mixture by lifting the gas pipe from the intake. This got the engine running, but only for a few minutes.

The gas quality could have been better as I used wood chips that were half-composted. The next test will have good-quality wood chips, and I expect better results. I have also fitted a pyrometer inside the hearth to measure the combustion temperature. This reached 750 degrees Celsius during my tests, so it should crack tar OK.

The gas cooler was perfect, with the pipe being touchable only 1 meter from the gas inlet. The other 6 meters were cool, so the thin-walled tube worked very well. I could shorten it to one length. But given summers here get to 40-odd degrees, extra cooling is probably worth it. The cooler the gas, the more oxygen available to burn, and hence, more power. So I will leave it alone.

Next Steps

The next test of the junkyard gasifier will be with a larger generator. I have a 5 Kva Subaru (Robin) generator with a failed electronic ignition. I have built a transistor ignition unit and am triggering it with a HAL effect sensor. This will allow me to vary the timing to optimize it for syngas.

Overall, I was pretty happy with the first test and now have some experience with wood gas. Apart from singed eyebrows, no damage was done with the backfire, but hey, isn’t that what they are for? Oh yes, don’t forget to wear safety glasses. I was, which probably saved me a trip to the hospital to remove bits of wood from my eyes.

If anyone else is around here (Northern NSW, Australia) is experimenting with gas, I would like to correspond with them. My e-mail is peterlaughton at y7mail.com.au.

Till next time, go gas !!!!!!!

Gasifier Outlet

Secondary Air Inlet

Secondary Filter