Wood Pellets

Wood pellets are heating fuels made from compressed biomass. The feedstock for Wood pellets is compacted sawdust or other waste streams manufactured by sawmills or other wood products. Other feedstock sources include rice husks, peanut shells, palm and coconut shells, groundnut shells, sugarcane biogases, crop stalks, coffee husks, paddy straws, sunflower stalks, and cotton stalks, tobacco waste, mustard stalks, soybeans husks, and many other Agro wastes. Of course, wood pellets also use complete trees, tree tops, and branches from logging operations.

In contrast to wood-based pellets, which are increasing in cost due to the growing scarcity of forest residues, grasses offer a more cost-effective and renewable option. Consequently, new solutions like faster-growing grasses must avoid removing whole trees and deforestation to supply the wood pellets market. A grass-based biofuel industry also has the potential to inject new cash into rural economies without depleting forest resources. However, attention will need to be paid to soil enrichment; otherwise, soil health will decline on these farmlands.

Processing

Wood pellets are manufactured in several types and grades as fuels for electric power plants, home furnaces, wood stoves, and other gasifier heating and power applications. Wood pellets are dense, easily handled, and with low moisture content; they burn with relatively high combustion efficiency.

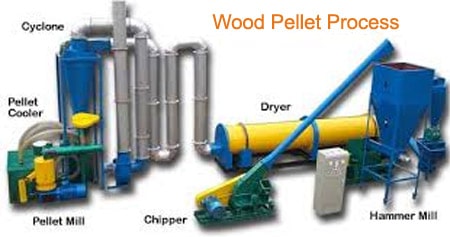

Chipping

The first part of the process is to reduce chunky biomass (wood, straw, grass) from large pieces down to chip size. Sawdust does not require this step when used to make wood pellets. There are two main types of chipping units, disc wood chippers and drum chippers which can be stationary or mobile units. The ultimate choice of disc or drum, along with sizing the unit, will depend on the chipped material.

Hammer Mill

Once the chunky biomass is chipped, the material can be fed into a hammer mill. A hammer mill powered by an electric or diesel motor grinds or hammers the straw, switchgrass, wood chips, or corn stalks ready for the pellet mill. Hammer mills are essential to creating high-quality wood pellets, as the raw material must be consistent and uniform before being fed into the pellet mill.

Dryer

Wood pellets are popular as they are a dry and uniform fuel with a moisture content below 10%. A flash or a rotary drum dryer removes moisture when the biomass has a moisture content above 15 percent. Drying costs can add to high prices due to the high demand, capital, and operating expenses. Air drying the wood biomass or circulating air through wood stored in bins or racks reduces costs. However, this is time-intensive and may require large storage areas depending on output volume.

Cyclone

The cyclone separates the dust and transports the dry hammered material to the pellet mill. The primary purpose of the cyclone is to reduce the dust and separate other noncombustible particles from the biomass.

Pellet Mill

The pellet mill or press is the heart of the wood pellet process. Small-scale mills are often simple screw or hydraulic presses, although many small units now offer flat or ring die mills. Combustion engines can power units in smaller mills or 3-phase electricity in larger systems. Manufacturing to a recognized standard reduces the risk of poor-quality pellets that crumble to sawdust or produce more ash. Our dedicated pellet mill page provides more information on the pellet mill page.

Pellet Cooling

This is often just a vibrating sieve or conveyor belt with directed airflow to cool the pellets. Generally, the costs for cooling are relatively small and don’t add that much to total pellet production costs.

Packaging and Storage

Good packaging and storage are essential to protect the pellets from absorbing moisture and breaking apart. Pellets exposed to humid environments absorb water, impacting combustion efficiency.